RAPID LIQUID PRINTING

Research completed at Self-Assembly Lab in collaboration with Christophe Guberan + Steelcase

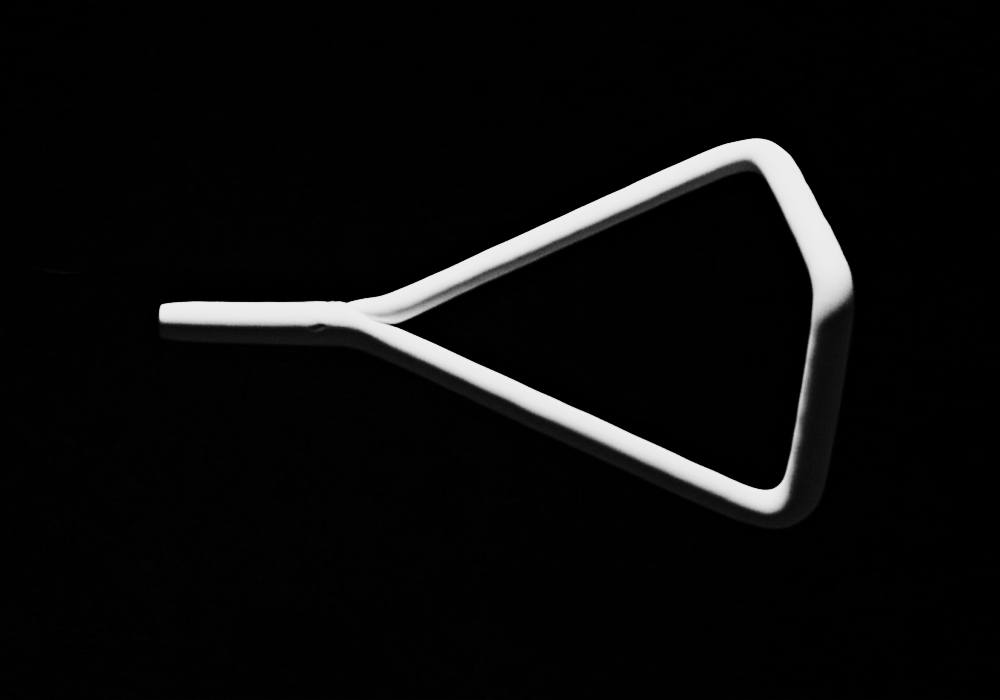

Today, the biggest challenges in 3D printing are small build volumes, long print times, and limited availability of materials. To address these challenges, we developed Rapid Liquid Printing (RLP), a novel printing process that uses a tank of reusable gel as a support medium. The gel allows users to print in all directions, rather than layer-by-layer, eliminating the need for printed supports and greatly decreasing the printing time. The RLP system is platform independent and able to be setup on any computer numerically controlled device. This flexibility drastically expands the build volume so that it is only limited by the size of the machine and tank of gel. The deposition system allows users to print with any one or two-part curable liquid. We have experimented with polyurethane rubber, plastic, foam, silicone, epoxy, UV-curable resins and plaster.

The RLP machine is composed of three primary components: tank of granular gel, control platform, and deposition system. The RLP system is flexible, allowing users to switch out any component for a larger or smaller one more appropriate for the specified production. We have demonstrated this flexibility by printing with four different control platforms and a variety of tanks and deposition systems. We printed with a 6-axis industrial robotic arm, two three-axis CNC machines, and a winch system.

Self-Assembly Lab Team. Kate Hajash, Bjorn Sparrman, Mattis Koh, Schendy Kernizan, Jared Laucks & Skylar Tibbits